Introduction to Digital Twin Technology

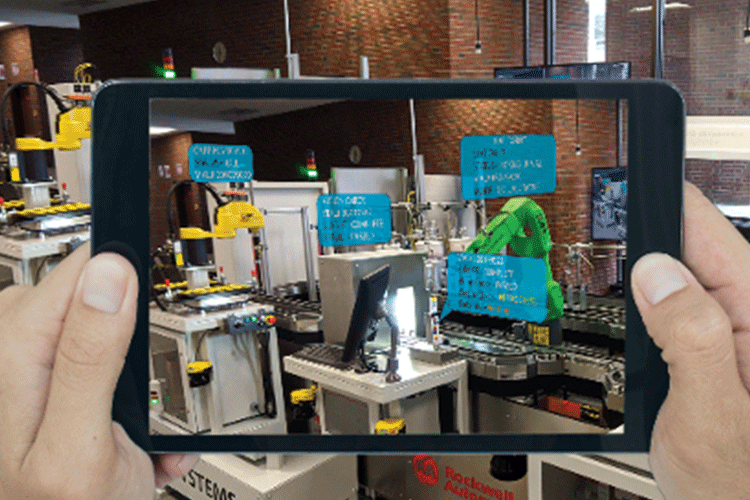

Habib Rahman, a professor of biomedical engineering and mechanical engineering, has been awarded $50,000 to work on an revolutionary project. The goal is to create a digital twin of a state-of-the-art vial filling system using augmented reality. This project is made possible by the Connected Systems Institute (CSI) on the University of Wisconsin-Milwaukee (UWM).

What is a Digital Twin?

A digital twin is a virtual replica of a physical system, corresponding to a machine or a process. It uses real-time data and simulation to predict how the physical system will behave. This technology has the potential to revolutionize manufacturing by reducing downtime, cutting production costs, and improving product development.

Benefits of Digital Twins

The use of digital twins can have a big impact on various industries. Some of the advantages include:

- Reducing downtime by predicting maintenance needs

- Cutting the time and value of product development

- Enabling predictive maintenance to stop equipment failure

Growing Demand for Digital Twins

The marketplace for digital twins is growing rapidly, especially in areas corresponding to machine and equipment health monitoring. In the long run, digital twins are expected to be utilized in environments which can be inaccessible or hazardous to humans, corresponding to:

- Space exploration

- Land mining

- Nuclear plants

The Project’s Objective

The foremost goal of Rahman’s project is to develop a framework for distant monitoring and data visualization of the vial filling system. To achieve this, the project will utilize various technologies, including:

- PTC Kepware

- Microsoft Azure IoT Hub

- PTC ThingWorx, an Industrial Internet of Things (IIOT) platform

Conclusion

The development of a digital twin for the vial filling system is an exciting project with significant potential. By exploring the capabilities of digital twin technology, Rahman’s project can pave the way in which for improved manufacturing processes and open up latest possibilities for various industries. As the demand for digital twins continues to grow, it’ll be interesting to see how this technology evolves and transforms the way in which we approach complex systems and processes.