Introduction to Augmented Reality

Advances in compact mobile devices have led to a rising interest in immersive human-digital interactions that exceed the capabilities of conventional flat-screen displays. As a result, augmented reality (AR) glasses or headsets are emerging as the following generation of interactive devices. These revolutionary tools enrich the user experience by seamlessly superimposing vivid visual information onto the actual world. To date, AR technology has demonstrated strong potential for applications in various domains, corresponding to navigation, engineering, military, gaming, and education.

Key Components of AR Glasses

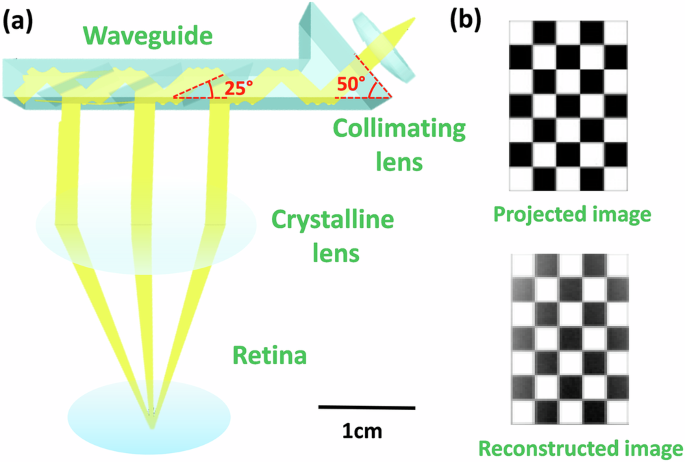

AR glasses or headsets incorporate quite a lot of essential components to offer immersive experiences for users. Among these, the optical see-through near-eye display (NED) stands out as considered one of the core elements. A NED typically consists of two essential components: a light-weight engine that generates and displays virtual content, and an optical combiner that merges the projected imagery with the user’s physical environment. Designing an efficient light engine for AR systems requires consideration of key aspects corresponding to image brightness, miniaturization, power consumption, heat dissipation, and backbone.

Optical Waveguide Design and Fabrication

Optical waveguide design and fabrication are intricate and complicated processes, posing substantial challenges for engineers and researchers. Lumus, a pioneer in waveguide technology, introduced the primary commercially successful geometric waveguide solution within the early 2000s. Their revolutionary design includes a triangular prism for coupling light into the waveguide and integrates an array of transflective mirrors to redirect light toward the user’s eyes. Light transmits through the waveguide via total internal reflection, ensuring efficient transmission. The use of total internal reflection inside the waveguide ensures efficient light transmission.

Geometric and Diffractive Waveguides

Both geometric and diffractive waveguides include their unique sets of advantages and downsides. The fabrication of geometric waveguides is a fancy process involving multiple detailed steps. It typically begins with depositing reflective materials onto glass substrates, followed by stacking these coated substrates with adhesive to create a layered structure. The stack is then sliced to the specified thickness, polished for a smooth surface, and cut into the required shapes. Although the fabrication process is complex, this structure offers several benefits, including a big field of view, high optical efficiency, and the absence of color dispersion. On the opposite hand, diffractive waveguides depend on periodic optical structures that could be fabricated using two important techniques.

Comparison of Waveguide Technologies

In contrast to the complex fabrication technique of geometric waveguides, which involves layer bonding, slicing, and polishing steps, the production of diffractive waveguides is comparatively simpler. However, the first limitation of diffractive waveguides is their susceptibility to paint dispersion, commonly generally known as the “rainbow effect”. This phenomenon arises from the sensitivity of periodic optical structures to the angle and wavelength of the input light, making it difficult to attain consistent optical performance across the visible spectrum. Although each geometric and diffractive waveguides hold strong potential for AR applications, their widespread commercialization is hindered by limitations in mass production capabilities.

Recent Advancements in Waveguide Fabrication

Recent advancements in PolyJet 3D printing and hybrid fabrication technologies have greatly transformed the sphere of additive manufacturing and the making of reconfigurable optical devices using fluid. Unlike conventional ultraviolet (UV) resin 3D printing, PolyJet printing uses water-soluble support materials, which lead to minimal surface blemishes on the finished part. This capability allows for the printing of overhangs without compromising the general quality of the printed surface.

Liquid Waveguide Technology

In this paper, we first designed and optimized a geometrical waveguide with a concentrate on fabrication feasibility. Subsequently, utilizing our patented manufacturing processes, we successfully fabricated a cheap liquid waveguide using silicone oil and a 3D-printed waveguide frame that integrated three dielectric reflectors for AR applications. Finally, we developed a custom-designed automated waveguide assembly system for future use. Our proposed method eliminates the necessity for complex machining processes and enables rapid prototyping. As far as we all know, the usage of liquid materials as an AR waveguide has not been previously reported, and it offers quite a few benefits.

Benefits of Liquid Waveguides

The high optical clarity of the liquid across a broad wavelength band minimizes scattering losses and improves overall performance. Unlike solid materials, liquids can conform to the form of the waveguide without applying additional stress or causing distortion. Using liquid because the medium eliminates reflector bending issues commonly encountered through the layer bonding process in conventional geometric waveguide fabrication. Additionally, liquid waveguides offer the advantage of self-healing minor surface defects, which improves the sturdiness and reliability of the optical system. These characteristics make liquid-based waveguides promising candidates for the rapid prototyping of AR waveguides.

Conclusion

In conclusion, the event of AR glasses and headsets is a rapidly evolving field, with significant advancements in optical waveguide design and fabrication. The use of liquid waveguides offers a promising solution for rapid prototyping and cost-effective fabrication of AR waveguides. With further research and development, AR technology is anticipated to revolutionize various industries and points of our every day lives. As the technology continues to advance, we will expect to see more revolutionary applications of AR in fields corresponding to education, healthcare, and entertainment. The way forward for AR is exciting and filled with possibilities, and it’s going to be interesting to see how this technology continues to evolve and improve in the approaching years.